Wartungsanleitung für die Sturmey-Archer AG Nabe und den Dynohub

Aus WikiPedalia

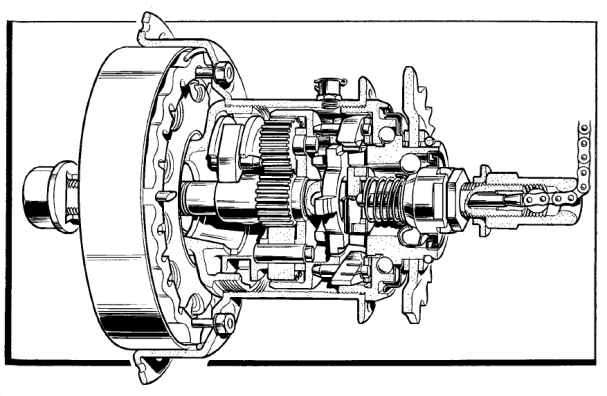

Hier wird eine Wartungsanleitung für die AG Nabe mit integriertem Dynohub wiedergegeben. Weitere Anleitungen kann man der Teileliste und der Explosionszeichnung entnehmen. Es gibt auch einen weiteren Artikel zu Dynohubs.

- Siehe auch

Auseinanderbauen

- Unscrew and remove the indicator rod from the axle. Then extract the Dynohub unit as follows:

- Remove the dynamo cone locknut, adjusting washers and spacing washers (if any), making a note of their arrangement so that they can be replaced in their original positions

- Remove the four magnet-fixing nuts and lock washers from the back of the hub shell and then remove the four magnet-fixing screws.

- Hold wheel parallel to the workbench and with a mallet tap the end of the spindle. This will cause the complete Dynohub unit to drop out. There is a shim washer between the cone and the armature, and it must be replaced when the hub is re-assembled.

- The magnet spacing ring can now be lifted out of the hub shell.

- Unless it is essential to do so, the armature and magnet should never be separated. If they are to be separated, a keeper ring should be used as otherwise the magnet will rapidly lose its magnetism. Even a moment's separation will cause loss of magnetism and a spanner placed across the magnet is useless as a substitute for a keeper ring [now unavailable, so don't separate the parts -- John Allen]. To separate the magnet and the armature, ag hubhold the Dynohub unit in the left hand with the terminal plate across the palm. Then fit a keeper ring over the armature and lightly tap the keeper with the palm of the right hand. The magnet will then slide off the armature on to the keeper. [Don't do it!]

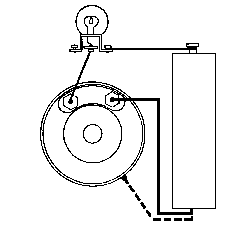

- At this stage it is wise to test the armature with a test meter. If there is no reading on the test meter there is a break in the winding. If a test meter is not available, a battery and bulb may be connected as shown in the diagram, and if the bulb does not light a break in the armature winding is indicated. A second test is to disconnect the lead from one of the armature terminals and touch the outer edges of the armature with the bare lead. If the bulb lights, this indicates a short circuit.

- Unscrew right-hand ball ring from the hub shell and withdraw the gear internals as described in the general instructions.

- Remove the low gear pawls, pins and springs. The pawl pins are easily pushed out of the planet cage to release the pawls and springs.

- Place the left-hand end of the axle in a vise and remove the right hand locknut, washers if any, cone lock washer and cone, making a note of their arrangement so that they can be replaced in their original positions.

- Lift off, in the following order, the clutch spring and cap, the driver, the right-hand ball ring and the gear ring.

- Remove the gear ring pawls, pins and springs. The pawl pins are easily pushed out of the gear ring to release the pawls and springs.

- Pull off the thrust washer and thrust ring.

- Push out the axle key and remove the sliding clutch and sleeve.

- Lift off the planet cage complete.

- Take out the pinion pins and remove the pinions from the planet cage.

- If necessary, because of a worn bearing surface or ratchets, the left-hand ball ring may be removed from the shell by means of special tool (DD10565).

Zusammenbauen

- If the left hand ball cup has been removed from the hub shell, replace it by screwing anti clockwise (it has a left-hand thread).

- Prepare the following subassemblies:

- Fit the ball cage into the driver, with the ring of the ball-retainer facing outwards and the recess in the dust cap also facing outwards. If a new ball retainer is being fitted, the dust cap also should be new. If the sprocket has been removed, see No. 23 below.

- Fit the balls (only 24) and the inner dust cap to the right-hand ball ring, making sure that the balls can revolve freely with the dust cap in place.

- Fit the pawls, pins and springs into the gear ring as described in the general instructions to 'The Re-Assembling of Sturmey Archer Hubs'. (The planet-cage pawls, pins and springs are not fitted at this stage.)

- Smear grease in the channels of the dust cap of the driver and in the recess of the right-hand ball ring. Do not use grease anywhere else.

- Hold the left-hand end of the axle in a vise, so that the slot for the axle key is above the sun pinion, and fit the planet cage.

- Ad the planet pinions and pins. (The small ends of the pins protrude.)

- Fit the sleeve (flange first), the sliding clutch with the recess over the flange of the sleeve and the axle key (with the flat of the key facing upwards), and screw in the indicator rod to hold them in that position.

- Fit the thrust ring and washer, making sure that the flattened ends of the key engage properly in the slots of the thrust ring. [These parts are combined into one in later production.]

- Fit the previously prepared gear ring sub-assembly.

- Fit the previously prepared right-hand ball-ring sub-assembly.

- Fit the previously prepared driver sub-assembly.

- Drop the clutch spring over the axle.

- Fit the cap and screw up the right-hand cone finger-tight. Then Loosen it back half a turn and lock it in that position with the special washer and locknut. On no account must the cone be unscrewed more than half a turn, as that would throw the gear mechanism out of adjustment.

- Invert the assembly in the vise and pour about two teaspoonfuls of good quality thin oil into the planet cage, then fit the planet cage pawls as described in the general instructions to 'The Re-assembling of Sturmey-Archer Hubs'.

- Screw up the left-hand cone.

- If the magnet and armature have been separated, take the magnet and keeper ring in the left hand and, with the right hand, lay the armature alongside it.

- While holding the magnet with the chamfer facing outwards, push the armature and the keeper through so that the magnet slides from the keeper on to the armature

- Fit the card disc (carrying patent numbers) inside the cover plate, with its notches opposite the magnet notches.

- Fit the cover plate over the magnet, chamfer inwards, making sure that the four holes in the cover plate are in line with the notches in the card and the magnet.

- Fit the metal spacing ring into the hub shell.

- Fit the shim washer.

- Push the complete dynamo unit into the hub shell, making sure that the holes in the cover plate are in line with those in the hub shell.

- Fit the magnet fixing screws, washers and nuts.

- Fit the spacing washers, adjusting washers and dynamo cone lock nut in arrangement noted when dismantling. Check wheel adjustment.

- If the sprocket has been removed from the driver, fit the outer dust cap over the driver before replacing the sprocket, and see that the dust cap is properly centerd on the flange of the driver. Replace the sprocket and spacing washers in the arrangement noted when dismantling, and add the circlip.

- Replace the wheel in the cycle frame and adjust the gear as described in 'The Installation and Adjustment of Sturmey-Archer Hubs.'

Werbung:

Quelle

Dieser Artikel basiert auf dem Artikel Servicing the Sturmey-Archer AG Hub and Dynohub von der Website Sheldon Browns. Originalautor des Artikels ist Sheldon Brown.

Weitere interessante Artikel zum Thema Sturmey-Archer

- S3X

- Die Sturmey-Archer ASC Fixed Gear Drei-Gang-Nabe

- Sturmey-Archer Naben

- Fehlersuche bei der Sturmey-Archer Sprinter Fünf-Gang-Nabe

- Die Sturmey-Archer Sprinter Fünf-Gang-Nabe

- Sturmey-Archer SW Drei-Gang-Naben

- Die Sturmey-Archer ASC Fixed Gear Drei-Gang-Nabe/Wartung der Sturmey-Archer ASC Fixed Gear Drei-Gang-Nabe

- Quadrant Shifter

- Dynohub

- SunRace

Weitere interessante Artikel zum Thema Nabenschaltung

Weitere interessante Artikel zum Thema Licht

Weitere interessante Artikel zum Thema Workshop

Weitere interessante Artikel zum Thema Sheldon Brown

- Sattelstützenmaße

- Ritzelabstände (Tabelle)

- Auswechselbarkeit von Vierkant-Kurbelaufnahmesystemen bei Innenlagern

- Kettenlinienstandards (Tabelle)

- Ein bequemer Sattel

- Nabenbreiten (Tabelle)

- Alles über Nabenschaltungen

- Shimano Nexus und Alfine Acht-Gang-Naben

- Reifengrößen

- Gute und schlechte Schnellspanner