Rahmen- und Nabenbreiten

In den letzten 40 Jahren habe sich die Fahrradantreibsstränge deutlich weiter entwickelt. Indexiertes Schalten hat viel von der Ratearbeit beim Schalten weggenommen. Integrierte Brems-/Schalteinheiten wie Campagnolos Ergo und Shimanos STI brachten die Möglichkeit, zu schaten ohne die Hände vom Lenker nehmen zu müssen. Kleinere Gänge helfen älteren Fahrern über Hügel zu kommen, die sie als jüngere Leute nicht gekümmert hätten. Nabenschaltungen gibt es mir mehr Gängen.

Während sich die Antriebseinheiten weiterentwickelten, sind Rahmen gleich geblieben und in vielen Fällen sind sie sogar schlechter geworden! Ältere Rahmen für Touren- und Freizeitfahrten werden deutlich komfortabler und entspannter als moderne Rahmen wahrgenommen, die oft für sportliches Fahren optimiert wurden. Ältere Rahmen haben mehr Platz für breitere Reifen und Schutzbleche. Damit sind sie praktischer für Fahrer, die nicht nur bei schönem Wetter unterwegs sind.

Und zusätzlich kann man einem Fahrrad durchaus sentimental zugetan sein, wenn es einen über tausende gute Kilometer begleitet hat.

Falls man ein geliebtes älteres Fahrrad hat, aber dem antiquierten Schaltsystem nichts abgewinnen kann, ist es nicht unvernünftig, es mit einem neuen Hinterrad, Schhaltwerk und Schalthebeln oder gar einer Nabenschaltung auszustatten. Der einzige Wermutstropfen jedoch ist die Frage, ob das neue Hinterrad in den Rahmen passt. Sehr oft ist die Antwort "Nein!", weil neuere Naben breiter sind und längere Achsen haben.

Jedoch sollte man das "Nein" nicht als Antwort akzeptieren! Ältere Rahmen - vorausgesetzt sie sind aus Stahl hergestellt, können so modifiziert werden, dass sie passen. Dieser Prozess wird oft als Kaltumformung bezeichnet, was eine aparte Umschreibung für das Aufweiten das Rahmens ist. In diesem Artikel wird beschrieben, wie man das anstellt.

Eine ältere Gabel benötigt unter Umständen auch eine Aufweitung, um zu einer modernen Nabe zu passen. Das ist der Fall bei älteren Raleigh Dreigang-Fahrrädern und vielen älteren farnzösischen Fahrrädern.

Falls man sich nicht sicher ist, ob der Rahmen oder die Gabel aus Stahl sind, kann man einfach einen Magneten benutzen. Hält der Magnet, hat man es mit Stahl zu tun und einer Kaltumformung steht nichts im Weg.

Einbaubreiten

Ein Fahrradrahmen und eine Gabel sollten zu den Laufrädern passen, die eingesetzt werden. Ältere Fahrräder hatten schmalere Einbaubreiten, können jedoch oft geweitet werden, um zu modernen Naben zu passen.

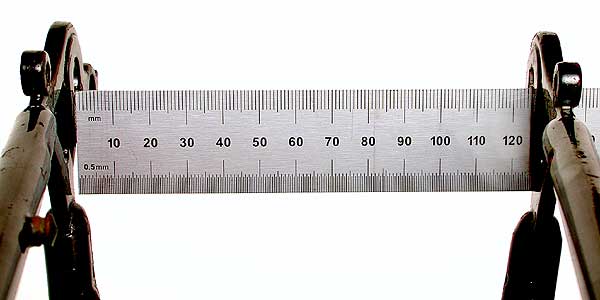

Die Einbaubreite eines Rahmens/einer Gabel wird innen zwischen den Flächen der Ausfallenden gemessen, wo sie mit den äußeren Muttern der Achse des Laufrads in Kontakt stehen.

Die Einbaubreite einer nabe wird an den äußeren Flächen der Konusmuttern gemessen, wo der Konus mit den Ausfallenden in Kontakt steht. Viele Patronenlagertypen haben jedoch keine Muttern, so dass die Einbaubreite an den äquivalenten Flächen der Achsenenden gemessen wird. Diese Einbaubreite wird für gewöhnlich Mutternabstand genannt - zu englisch: OLD oder Over-Locknut-Distance).

Standardbreiten

Eine Tabelle bekannter Nabenbreiten findet man hier. Die Seite über Kettenlinie und Mutternabstände bei Fahrrädern mit Nabenschaltung beinhaltet Mutternabstände dieser Naben. Im Zweifelsfall sollte man immer messen!

Die gesamte Achsenlänge ist bei Schnellspannmechanismen gewöhnlich 11 mm breiter als die obigen Mutternabstände der Nabe. Auf jeder Seite sind das 5,5 mm. In der Praxis kann die Achse ein ganzes Stück kürzer sein. Sogar 1-2 mm Überstand über die Muttern reicht aus, um die Achse ausrichten zu können. Wenn man also eine Nabe auf die nächste Breite umspaceren möchte, muss man nicht unbedingt die Achse ersetzen.

Einstellen der Achsenbreite

Hubs with conventional threaded axles can be adjusted for wider spacing by adding spacer washers, preferably between the cones and the locknuts.

For single-sprocket wheels, it is generally best to add equal spacers to each side. This way, the rim remains centered in the frame.

With most internal-gear hubs, spacers can be added on the left end of the axle, and with some also on the right, as described on the page that gives their overlocknut distances.

If you are increasing the spacing of a derailer-type wheel for the purpose of increasing the number of sprockets, you'll generally be adding space to the right side only. If you do this, you'll need to "re-dish" the wheel, by pulling the rim to the right. This is done by tightening the spokes on the right side of the wheel and/or loosening those on the left side. If you don't have experience with wheel trueing, this may be a job you're not yet ready for.

The downside of this is that pulling the rim to the right increases the tension difference between the left and right spokes, resulting in a somewhat weaker wheel.

Conversely, if you're installing a wheel in a wider frame than it was meant for, adding the spacers to the left side will allow you to increase the strength of the wheel by moving the rim to the left.

Achsenlänge

Typical quick-release axles are 11 or 12 mm longer than the spacing of the hub locknuts. This gives 5.5-6 mm of axle protrusion on each side. You don't actually need nearly this much, so for respacing hubs to wider spacing, if you're not adding more than, say, 5-6 mm of spacers, you don't need a new axle. As long as you have 2 or 3 mm sticking out on each side, that's plenty.

One of my own bikes is set up with the axle cut off flush with the locknuts, and even this is no problem in use, though it is slightly trickier to align the wheel when installing it. See my page about my fixed-gear mountain bikes.

Anpassen der Rahmen-/Gabelbreite

If your frame or fork is made of steel, you can change the spacing to accommodate different hub spacing. This is most commonly done to widen the spacing, to permit the use of a cluster with more sprockets than the frame was built for.

Note, if you're not careful, you can do serious damage to your frame or fork this way!

If your frame or fork is made of aluminum or carbon fiber, do not attempt to re-space it: these materials are not suitable for "cold setting."

If in doubt, try the magnet test: if a magnet won't stick to it, don't try to re-space it!

Muss man ständig seinen Rahmen auseinanderbiegen?

Ideally, the frame spacing should exactly match the hub spacing. This makes for easiest wheel replacement. In practice, however, there's a fair amount of latitude in fit. In fact, when the first 130 mm 8-speed hubs were introduced, they had locknuts with beveled sides, so that you could "spring" apart the rear triangle of a frame made for the then-standard 126 mm spacing.

A conventional cup-and-cone hub tolerates some bearing misalignment, and in general, you can safely go up one size in spacing this way, just springing the frame apart. I can't give you an absolute guarantee that this won't cause damage, but the odds are very much in your favor.

Having to spring the frame every time you replace the wheel is inconvenient, especially if it has a quick-release axle .An internal-gear hub or sealed-bearing hub is very likely to be damaged if the dropouts are not parallel. In this case, cold setting is the better way to go.

If you're going up more than one size, say from 120 to 130, or from 126 to 135, you should definitely cold set the frame.

Rahmen aufweiten

There are a number of ways to do spread a frame. Probably the easiest way is to use a lever. A piece of 2 x 3 or 2 x 4 lumber, roughly 5-6 feet long works well for this:

Remove the wheels, fenders and any seat-tube mounted bottle cage. Lay the bicycle on its side with the handlebars turned to face upward If you are unsure about the strength of attachment or tubing at the chainstay or seatstay bridge, you might clamp them together with supports made by drilling a block of soft pine wood and then sawing it in half along the middle of the drill hole. This precaution is usually unnecessary, but it might be a good idea if you are making a major change in spacing. Insert the lumber through the rear triangle, so that it goes underneath the upper rear forkend, and above the seat tube. The lumber should extend out past the rear end of the frame. Place the far end of the lumber onto a chair, crate or other raised structure, so that only the head-tube/fork area of the bike is in contact with the floor. Press down gently on the lumber where it crosses on top of the seat tube. Measure the spacing to see if it has changed. If the spacing hasn't changed, try again, pressing a little bit harder. Repeat until you get a result, applying a bit more force each time, until the spacing has increased by about half the total amount you are seeking. Turn the bike over, and repeat for the other side.

In the illustrations below, the stays will be bent to the left (up in the photos) by pressing down on the end of the 2 x 4. The other end of the 2 x 4 is on top of a stool. The longer the 2 x 4, the less force is needed. frame-spacing left frame-spacing right The 2 x 4 is under the left forkend, widening the spacing by pulling the left side upward The 2 x 4 is under the right forkend, narrowing the spacing by pulling the right side upward The bike does not actually need to be stripped down this far, most parts can remain in place.

Eine Gabel aufweiten

A front fork can't be spread the same way as the rear of a frame, because you can't lever against the seat tube. Generally, the front fork is spread by pulling the blades apart from one another. Better-equipped bike shops have jigs to align fork blades. This can be done with a hub axle, placing axle nuts in between the fork blades. Fine adjustments may be made with a rubber mallet.

Asurichtung (Symmetrie) prüfen

It is important that both forkends be equally far from the centerline of the frame or fork, otherwise the bicycle won't track properly. Ideally, the frame alignment should be made using a special fixture that clamps the frame by the sides of the bottom bracket shell, and takes those faces as the reference point for all other measurements. This requires special tooling beyond the reach of the home mechanic or small bike shop.

Assuming that a frame was built straight to begin with, alignment can be checked by comparison of the rear triangle with the front triangle. Park makes an adjustable gauge for this, the FAG-2, and this is what most bike shops would use.

The usual "home mechanic" technique, however requires nothing more than a piece of string and a ruler. This is a bit slower than using a purpose-built gauge, but gives good results, if you are reasonably careful. The String Method:

string test

Tie a piece of string to one rear forkend so that the string runs along the outside of the forkend. Run the string around the front of the head tube and back to the other rear forkend, as in the photo. You could also run the string to the opposite side of the head tube from each dropout and loop it around, to reduce the spacing from the seat tube. Pull the string taut, making sure that it's contacting the same part of each forkend Use a ruler to measure the distance from the string to the side of the seat tube where they cross. Take this measurement on both sides. It should be the same on each side. If the spacing is as desired, and the string test is correct, you're almost done. If not, you'll need to go back to levering with the lumber to correct any error. If you find that you've overcorrected on one side or the other, the same basic approach can be used, except that you lay the bike down so that the stays that are too far out are facing down. Run the lumber under the bottom forkend, and, again, over the seat tube, then press down as before.

Gabel prüfen

A bike shop checks symmetry of a front fork with its special jig, but symmetry can also be checked roughly by installing a wheel into the fork and testing whether the rim centers between the fork blades. To be sure that the wheel itself is centered, turn it over and try it the other way. The rim should be the same distance from each fork blade after being turned over. Minor adjustments for symmetry can be made with a rubber mallet. Testing for symmetry of a front fork is more difficult than with the rear of a frame.

Ausrichtung (Parallelität) der Ausfallenden prüfen

Spreading a frame or fork will cause a slight change in the angles of the forkends, so they will no longer be exactly parallel to one another (assuming they started that way.)

Check for parallelism after spreading a frame or fork, or whenever you are concerned that forkends might be out of parallel -- if the bicycle has been crashed, a forkend is visibly bent, or a wheel is hard to install and an axle nut or quick release feels "springy" rather than clamping down tight.

Procedures for checking and adjusting parallelism have been moved to another page.

Sol ich das wirklich machen?

This job isn't for everybody, but it's not rocket science either. Many shops are reluctant to undertake this sort of operation, either because of fear of liability or because they want to sell you new bike. Although it seems fairly alarming to deliberately bend your frame, it is really not that cataclysmic an operation, and can be very worthwhile if it allows you to keep riding an old friend, with the advantages of a modern drivetrain.

Siehe auch

Quelle

Dieser Artikel basiert auf dem Artikel Bicycle Frame/Hub Spacing von der Website Sheldon Browns. Originalautor des Artikels ist Sheldon Brown und Ergänzungen von John Allen.

<img size=1x1>http://vg04.met.vgwort.de/na/dce9269d70ff4c9d88be0032724ef465</img>