Sturmey-Archer SW Drei-Gang-Naben

Zur Sturmey-Archer SW Nabe existieren Geschichten von problembehaftetem Betrieb, um es vorsichtig auszudrücken. Die Erfahrung der meisten Leute mit dieser Nabe waren negativ, daher ist diese Nabe heutzutage eher selten anzutreffen. Während die Nabe an sich sich nicht als praktikabler Ersatz für die ehrwürdige AW Nabe herausstellte, gab es nichtsdestotrotz einige faszinierende Designaspekte, die ein moderates Interesse an dieser Nabe festhalten sollten. tatsächlich wurden funktionierende SW Naben als "sehr angenehm", "fast geräuschlos", "effizienter" usw. beschrieben. Brian Heyes Interesse stammt aus seinem Kauf eines 1959er Robin Hood Sports, das mit einer schlecht funktionierenden SW ausgestattet war. Er hatte vorher nie ein Fahrrad, das mit einer SW ausgestattet war, gefahren und war hingerissen von der Stille dieser Nabe im Vergleich mit einer gewöhnlichen AW Nabe. Dieser Artikel ist an andere SW Besitzer gerichtet, die ihre müde alte Nabe widerbeleben wollen und ein Stücke Sturmey-Archer geschichte atmen möchten. Unter Zuhilfenahme einiger Ersatzteile vom Müll, vorsichtiger Montage und ein wenig Glück kann man diese Dinger vernünftig wieder ans Laufen bringen und wenn man bereit ist ein paar Klickgeräusche beim Freilaufen lassen in kauf zu nehmen, bekommt ma sie sogar ziemlich gut wieder hin.

Neben der von außen offensichtlichen Unterschiede zur gewöhnlichen AW Nabe (kleiner und leichter[1]) gibt es weitere Unterschiede in den Übersetzungen, da die SW eine sehr breite Übersetzungsbandbreite mitbringt:

| Gang | Nabe und Übersetzung | |

|---|---|---|

| AW | SW | |

| Hoch (Dritter) | 133% | 138% |

| Normal (Zweiter) | 100% | 100% |

| Niedrig (Erster) | 75% | 72% |

- Siehe auch

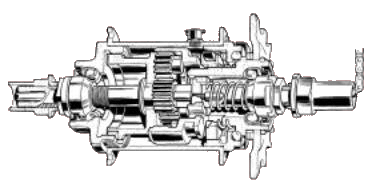

Vergleicht man die SW mit einer gewöhnlichen AW Nabe, bringt ein Blick ins Innere einen vllständig anderen Designansatz des Planetenegtriebes für Fahrräder hervor. Faktisch gibt es kaum ein Bauteil in der SW Nabe, dass mit irgendeiner anderen Sturmey-Archer nabe austauschbar wäre.

Im Folgenden werden der erste, zweite und dritte Gang jeweils als "Niedrig", "Normal" und "Hoch" bezeichnet. Zur klaren Darstellung sind einige Teilenummern in Klammern aus dem 1956er Hauptkatalog, der am Ende des Artikels verlinkt ist, ausgewiesen. Am Ende des Artikels folgen einige Verlinkungen zu weiterführenden Informationen.

Lastverteilung auf drei Punkten

Der erste augenfällige Unterschied ist der interne Aufbau, der statt der vier Planeten, bei der SW auf drei Plantenräder, dreizinkige Mitnehmer, drei Sperrklinken (zu jeder Zeit), eine Kupplung mit drei Nocken, usw. aufsetzt.

Unter Last tendieren Aufbauten mit drei Kontaktpunkten dazu, diese gleichmäßig auf alle diese Stellen. Bei einer Lastverteilung auf vier Punkte, sind immer einige hoch belastet und manche sehr wenig belastet. Das gilt solange, bis ein gewisser Verschleiß einsetzt und die Last gleichmäßig verteilt wird. Das ist analog zu einem dreibeinigen Melkhocker, der das Gewicht des Melkenden gleichmäßig auf alle drei Beine verteilt, während das vierbeinige Pendant das nicht macht, bis die vier Beine soweit abgeschabt oder eingedrückt sind, dass das Wackeln unterbunden wird.[2] Dieser Aufbau führt dazu, dass man kleinere Räder nutzen kann, weil diese immer die Last unter sich aufteilen - das ist vermutlich der Grund, warum die Designer bei Sturmey-Archer die Größe der Nabe gegenüber vorherigen Design verkleinern konnten. Nach dem Kenntnisstand von Sheldon Brown waren Probleme mit den Zahnrädern bei Sturmey-Archer Naben nicht verbreitet.

Ein weiteres Merkmal der Lastverteilung auf drei Punkte war, dass die ringförmig angeordneten Bauteile sich selbst zentrierten. Das merkt man am deutlichsten bei den Kupplungsbauteilen der SW: die Mitnehmer des Zahnkranzes und dem rechtsseitigen Sperrklinkenring. Diese Bauteile haben drei passenden Kombinationen und haben gerundete Oberflächen. Unabhängig von der Kombination verteilt sich die last immer gleich. Diese gleichmäßige Lastverteilung ist und war das eigentliche Ziel.

Sperrklinken ohne Federn

Das bei weitestem berüchtigtste Merkmal dieser Naben waren allerdings die federlosen Sperrklinken. Diese kleinen Schmuckstücke aus Irritation sind freischwebend, halbmondförmig und aus gehärtetem Stahl (ungefähr 7,5mm lang und 4,8mm breit) gefertigt. Sie ähneln einer Scheibenfeder, wobei die normalerweise gerade Oberfläche hier gekrümmt ist, so dass diese einem Halbmond oder Lächeln ähnelt. Sie werden dazu benutzt, Drehmoment in die eine Richtung zu übertragen und ermöglichen freilaufen lassen in die andere Richtung. Der Freilaufeffekt wird durch eine Schaukelbewegung durch die vorbeilaufenden Rampen und Täler des linken und rechten Kugelrings erzeugt. Das ist tatsächlich recht schlau gelöst und erinnert an einen Hemmunsgmeachnismus mechanischer Armbanduhren. Während man freilaufen lässt, sind die Sperrklinken für den Fahrer nicht hörbar. Wenn man jedoch das Laufrad vom Boden anhebt und mit den Ohren ganz nah kommt, kann man bei drehendem Rad einen ganz leises klickendes Geräusch hören.

In Fahrtrichtung dient die Ausrichtung der Rampen und Täler dazu, eine Kante jeder Sperrklinke einzufangen und sie gegen die Täler der Kugelringe aufzurichten, um relative Rotation des Sperrklinkenträgers gegenüber dem Kugelring zu verhindern. In jeder möglichen Übersetzungsposition sind immer genau drei Sperrklinken aktiv, so dass die Kräfte gleichmäßig verteilt werden. Die Sperrklinken sind einzeln viel kleiner als die Sperrklinken einer AW Nabe. da sie aber immer zu dritt statt zu zweit aktiv sind, sind sie insgesamt mindestens so widerstandsfähig wie die zwei Sperrklinken in der AW Nabe.

Interessanterweise wurde dieser Freilaufmechanismus zurückdatierbar in der origionalen Sturmey-Archer Dreigang-Nabe von 1902 eingesetzt. Der Mechanismus wurde als "Micrometer-Typus einer federlosen Kupplung" bezeichnet. Der Name deutet auf das Unternehmen hin, dass diesen Mechanismus erfunden hat[3].

Kupplung

Ein weiteres interessantes Merkmal, das die SW von der AW unterscheidet, ist die Rutschkupplung, um in den niedrigen Gang zu schalten. Bei der AW wird in den niedrigsten Gang geschaltet, in dem die Kupplung mit den vier Zinken gegen die Unterseite der beiden normal/höchster Sperrklinken schlägt, so dass diese mit Gewalt ausgehebelt werden und das Drehmoment auf ein anderes Paar Sperrklinken wirkt (niedrigster Gang). Beim Sperrklinkendesign der SW gab es keinen solchen Weg, daher wurde der komplette Sperrklinkenring aus seiner Position bewegt (entkuppelt), so dass die linksseitigen Sperrklinken aktiv wurden. Dieser Aufbau erfordert eine zusätzliche Feder und mit dieser zusätzlichen Versteifung ist der Schaltwiderstand höher. Sheldon Brown vermutete daher, dass Sturmey-Archer deswegen eine zweiteilige Schaltkette einführte, die mehr Gewindeschaftlänge wegen der höheren Bruchsicherheit zur Verfügung stellte (das war aber wohl nicht notwendig, weil spätere SW Modelle eine Standardschaltkette einsetzten). Andere Naben mit hohem Schaltwiderstand hatten ebenfalls eine zweiteilige linksseitige Schaltkette (zum Beispiel die FW).

Auskrangende Planetenräder-Schäfte

Die Planetenräder laufen auf dicken Schäften, die ein integraler Bestandteil des Planetenkäfigs sind. das ist anders als bei der AW Nabe, bei der die Schäfte abgestuft sind. Die Schäfte in der SW werden nicht von beiden Seiten des Getriebes getragen (auskragende Anordnung) und benötigen mehr Durchmesser, um Bewegungen in höheren Gängen zu widerstehen. Dicke Schäfte erhöhen den Widerstand im Betrieb. das geht möglicherweise so weit, dass es den Vorteil, dass es nur drei Planetenräder gibt, ausgleicht.

Was waren die Probleme?

Sperrklinken

Despite the theoretical advantages of the 3-planet design, the SW hubs were rather disappointing in practice, particularly in the operation of their pawls and gear rings. The most common symptom was skipping under load in normal or high gear. Interestingly enough, low gear (the most highly stressed condition for these pawls) seldom produces this problem. The reason for skipping in normal and high is twofold — in one case it's due to worn clutch dogs, to be described later, and in the other case, it's due to problems with the pawls. Under even non-abusive service, the pawls can develop chips and indentations indentations and can wear to the point of not being picked up by the ratchets. The ultimate cause of this premature wear would surely have been evident in the development testing of this hub design, thus preventing the eventual embarrassments in actual service. So what went wrong?

This question may never be fully answered, but I'll offer some speculation: The development testing most probably involved some initial hand-built prototypes that did not use production tooling, and as such, were probably machined rather precisely by the best machinists Sturmey-Archer had. Under these conditions, the SW design probably was proven handily, and authorization to go into full-scale production ensued. With production tooling, however, the SW design really fell apart due to the sloppy techniques common to manufacturing plants of the time. Remember, these hubs had to be relatively inexpensive to prove economically viable. Evidence of this abounds when one examines the SW parts. Very rough machining and sloppy fit of most moving parts is usual. (An engineering colleague of mine in our Gear Technology group described the gear machining as "horrible"). This is not meant as a slam against the quality of Sturmey-Archer workmanship: most of the parts are hardened, accentuating the machining marks more than normal, and again, these hubs had to be economical. Also, powder metallurgy was not available as a viable option in 1955. As the old saying goes, "You can have it good, fast, or cheap — pick any two."

Consequently, producing a design such as the SW in this environment must have proven nearly impossible. Because of the necessary loose fit of parts (to ensure simultaneous interchangeability and low cost), the concept of 3-point contact went out the window, except when the occasional hub had all the right combination of parts. In other words, because of the lack of precision, the 3 pawls were not simultaneously lifted into jamming position; instead only one or two pawls typically engaged at any one time (you can see this on a partially disassembled hub turned by hand). The hub still functioned under these conditions, albeit somewhat roughly due to internally-offset loading. This condition led to damage, since the pawls were not designed to take all the driving forces single-handedly. Couple this with the typical abusive behavior found in youth, and the results should have been predictable. Occasionally, the right combination of parts must have produced a hub that reliably engaged all three pawls and therefore gave good service.

Tony Hadland reports that:

In 1995, Sturmey-Archer enthusiast Jim Gill produced a report on the SW's shortcomings and how they might be resolved. He noted that slipping occurred in direct and high gears but not in low gear. After extensive testing, he concluded that invariably one or two pawls failed to seat fully against the ratchet teeth. The gear ring and pawl ring were thus no longer concentric so that with each turn of the hub the dogs which locked these two items together moved very slightly in relation to each other and eventually they "walked" apart, causing a slip.

He concluded that the SW would have worked fine if Sturmey-Archer had a) slightly increased the depth of the well for the pawls and b) fitted each pawl with a spring and modified the profile of the ratchet teeth in the ball cups."[4]

This explanation makes good sense and links the two failure modes of pawl problems and worn gear ring dogs. However, as I mention below, merely spring-loading the pawls provides an excellent solution to the slipping problems in normal and high gear.

The metallurgy of the parts also played a vital part in the performance of these hubs. On the one hand, the pawls and pawl rings must be made from very hard, high strength steel in order to withstand the extreme stresses (see below) when pedaling hard. On the other hand, such high hardness makes it difficult for the parts to "wear in" together evenly; it's the proverbial Catch-22. It would be interesting to know whether Sturmey-Archer designers ever experimented with various heat treatments on the pawls in order to arrive at an optimum hardness.

A stress analysis of a single pawl operating under a 200-pound pedal force is shown in the stress on single pawl animation accompanying animation. The stress levels are extremely high and demonstrate why the pawls typically chip and/or indent. If all three pawls would engage at once, the stress would be reduced by a factor of 3 and the pawls would then probably survive quite well. Under the "overload" conditions, the von Mises stress at the "indent" portion of the pawls is approximately 300ksi, and 800ksi at the tip, if anyone is interested.

Verschleiß

One area of wild speculation as to the contributing factors of hub demise is that of lubrication and wear. I have found pawls that were not chipped and not dented, but were rather simply worn down on the tips of the crescent, rendering them inoperative (see picture at right). worn pawls It is unclear whether such a condition is caused by partial engagement in the ratchets or merely from the millions of oscillations imposed by coasting. The latter appears a bit more likely since the wear seems to occur equally on either end. It may be due to the presence of grit in the lubricating oil, or the forces required to rock the pawls back and forth, or a lack of lubrication, or a combination of these. Lack of lubrication could be due to bicycles' having kickstands on the left side and therefore leaning to the left — any oil in the hub will tend to migrate to the left side, thus starving the right side pawls. Lack of lubrication may also be due to overly heavy lubricant — grease in the pawl sockets is recommended for ease of assembly, and perhaps this grease contributed to excessive pawl wear due to its high viscosity. Who knows? I hope I am not provoking a "holy war" on the selection of oil, but my recommendation is for a fairly-light oil such as ATF or the like, preferably synthetic. Cold-weather operation may prove troublesome with too heavy an oil.

Other high-wear areas include the planet cage-to-axle pivot, the gear spacer ring, and the gear ring-to-ball ring interface on the right side. I have seen a lot of sludge build-up around the planet cage pivot, and this may be the reason for a design change from the original conical fixing plate to a nut-and-spacer arrangement.

Rauer Lauf in verschiedenen Gängen

These hubs often run rough in low and high gear (normal gear does not load the planetary gears, and is always smooth). This roughness, a result of misalignment of the gear ring and planet cage, can be felt easily by the rider as and is due mostly to loose cone adjustment, sloppy thread clearance from the axle to cones, bent axles, or possibly single-pawl engagement. Also, with this and some other Sturmey Archer 3-planet designs, the pinions have a modified tooth form to allow the "wrong" number of teeth to be used on the pinions (the SW's pinions have 15 teeth, but would normally be designed with 16 to match the 52-tooth ring and 20-tooth sun). This design choice allowed the pinion teeth to be stronger, but also inevitably meant that the smoothness suffered. Furthermore, the gear teeth are very crude, possibly also contributing to the roughness. A test hub with the gear-ring teeth ground down about .005" and their edges radius-ground has improved, but not eliminated the roughness. However, another test in which tight-fitting cones were chosen from the parts bin virtually eliminated the perceived roughness. Chainstay-dropout alignment has also been shown to affect the smoothness; make sure your frame is properly aligned.

Überspringende Hohlradmitnehmer

My original 1958 hub's internals had worn, sloping gear-ring and pawl-ring dogs which permitted the pawl ring to slide or "cam" out of engagement (against the spring force) in normal or high gear. If normal gear was selected, this motion slammed the hub into low gear, surely taking a great toll on the gear-ring internal splines (mine were really chewed up) and may be the main cause for low gear pawl chipping. This "camming out" effect may be what Tony Hadland is identifying as the primary cause of trouble with this hub4. Camming out is more prevalent in high gear than normal because a rider typically transmits more torque in a slower/higher gear. As mentioned above in the section on pawls, the slipping of these dogs can be related to problems with incomplete pawl engagement, although even with perfect pawl operation, clumsy shifting can result in partial engagement of these dogs, again leading to slippage.

Designänderungen von Sturmey-Archer

Mid-19583 seems to be a point for many design changes to the hub, presumably done to increase its reliability. 1958 is also the year that the AW was re-introduced and apparently made "standard" again. The last year for the SW was 1960, but I do not know if there were any late changes, as I have no hubs dated later than late 1958.

Left to right indicator

The left-side indicator with right-side toggle chain was changed to a conventional right-side indicator spindle around mid-1958. This required a change to the axle key; instead of a simple through hole, it now had a threaded hole to accept the indicator spindle. The models originally equipped with right-side indicator spindles also do not have their axles drilled all the way through.

Pawl ring (L11)

A few NOS pawl rings I have encountered are machined differently than all of the others. There is a subtle different dog profiles change to the dog faces where they contact the mating surface of the gear ring. I'm not sure which configuration is newer. The color from heat treatment is also different, suggesting a change. Based on an inspection of a seemingly original early 1958 hub, the pawl ring on the left may actually be the newer design. This "blunter" dog design makes sense if wear reduction was the goal.

Pawls (L12)

I have encountered at least two different pawl configurations, differing in the dimensions and appearance (NOS parts). One type, shown in the accompanying pictures, has a bright finish and has a height of .170" by a width of .335", while the other type measures .160" by .330" and has a natural metal finish. The tips of the larger pawl are also a bit blunter. I guess that the larger pawls were the result of an attempt by Sturmey Archer to improve performance, as they really do work better. I'm not sure of the hardness differences between pawls, if any, but I expect that all pawls are through-hardened. I have also seen some variations on the width, but not by much from the nominal width of 3/16" (.1875"). The larger pawls are understandably a bit noisier in operation, but still not very noticeable to the rider. If you have a choice, use the larger pawls on the right side, since they have better engagement performance.

Planet cage (L2Z)

gear rings At least three planet-cage designs were fielded over the years, with the original design having a smooth outside diameter adjacent to the low-gear pawl sockets. (This configuration appears in the illustrations of the 1956 master catalogue.) Later, a thin ridge was added next to the pawl sockets, presumably to aid in the centering of the planet cage relative to the ratchets, but possibly also to improve the gear alignment. The last change was apparently to increase the width of this ridge to reduce the attendant wear. This feature may be the big reason these hubs were not known to give too many "skipping" problems in low gear.

Gear ring (L10)

At least two different gear-ring designs have been made. Early versions did not have an extra lip at the right side ball ring interface — they simply ran against the sides of the ratchets. Apparently, there was too much wear, and later versions added a lip to run against the inboard side of the ball ring.

Planet cage locating on axle

Early versions of the SW used a conical fixing plate (L4) and special washer (L24) to retain the planet cage on the axle. The conical fixing plate was permanently deformed into position using a hollow punch to flatten it in place. This feature was later deleted and replaced with a spacer and hex nut, presumably for easier servicing, but also (perhaps) to correct a problem with excessive wear's resulting in too much internal play (I have some very worn examples with over 1/8" play). The newer arrangement certainly is more robust than the original.

Reparieren der defekten/rutschenden SW

The first thing one should do when contemplating repair of these hubs is to become thoroughly familiar with the design. This is best accomplished by viewing the cutaway drawing, exploded view and parts list available from Tony Hadland's site. All the following suggestions assume that the reader has these resources available.

Schnelle Repararturen

Slipping

If your hub is slipping as soon as pedal force is applied in low gear, the problem is probably with the left-side pawls. One of the easiest ways to get it working again (provided the pawl damage is minimal) is to disassemble, clean, and swap the position of the low-gear and high-gear pawls (left side to right side). Furthermore, it should be evident from the dimple and/or chips which direction they were originally oriented in their respective sockets. Switching the direction will load the pawls in the opposite direction, and provided they are free to oscillate and are not too worn, is essentially equal to using new pawls. Since NOS pawls are as rare as hen's teeth, it makes good sense to use up all the available life from each pawl. You may also want to experiment with individual pawl locations until the right-side pawls all consistently pick up and fully engage. Check this by assembling the hub internals and operating the ratchet by hand. I do not recommend applying grease to the pawl sockets as an installation aid; a drop of oil works well enough to keep pawls in place while assembling, and you won't have to worry about the potential sluggish engagement of pawls.

If your hub is slipping only in normal or high gear, the problem can also be due to worn pawl-ring dogs in addition to pawl problems, and a simple fix can be affected by increasing the spring's engaging force by stretching the large spring (L15) to increase its free length. This increases the trigger pull into low gear and probably also accelerates wear, so it's important not to overdo it. If the pawl-ring dogs are not too worn, this may be all that's needed to restore proper operation, but in the long term, it may be necessary to regrind the dogs or replace the gear ring and/or pawl ring.

Adjustments

Let me begin here by stating that I assume the reader is very familiar with Sturmey-Archer gearing in general, especially with the ubiquitous AW. If you are new to three-speed planetary hubs, I suggest you find an AW hub and take it apart for practice. Having said this, there is only one area of SW adjustment that requires special attention: the bearing cones. Unlike the tolerant AW, the adjustments should be as close as possible to zero "play". Tight adjustment ensures the best-possible centering accuracy, which in turn improves the chances of three simultaneous pawl engagements. If the bearing adjustments are too loose, you will almost certainly end up with pawl problems, even with new parts. The importance of keeping the centering accuracy good is evidenced by the design evolution of the low gear side's planet cage having a centering lip added.

If you experience gear roughness, the first thing to check is cone adjustment. If nothing changes, you might try installing the axle rotated 180 degrees in the dropouts or try a different left-side cone.

The adjustment of conventional indicator spindles is best accomplished (in my opinion) with the Sheldon Brown method: in low gear, the chain should have just a tiny bit of extra travel when pulled further outward, and in high gear the cable should be slack. Since many of these hubs do not have indicator windows in the right axle nut (N200) (presumably due to the change mentioned next), this is the only practical way to adjust the spindle, unless replacement nuts with windows are used.

Indicator spindles

Conventional right-side indicators can replace the two-piece indicators even if the hub originally was not configured this way. The only trick is finding a threaded axle key made for the SW or making your own. Fortunately, making your own is easy — just whittle down the ends of an axle key from any AW hub until it fits properly in the clutch sleeve and sliding clutch. The two-piece, left-side indicator/toggle chain arrangement is easier to adjust properly, however, and I recommend keeping this arrangement unless you have damaged parts.

Planet (L5) installation

Make sure burrs on the pinion teeth are ground smooth. If the burrs face the spacer ring (L6), it will experience excessive wear and probably an increase in drag until the parts wear in. Allowing things to wear in on their own can really chew up the spacer ring, however, so I suggest removing any burrs from the planet teeth.

Reparaturen und Modifikationen für ein langes Laben

Parts selection

When rebuilding an ailing SW, the best approach is to use all new parts, but most of these parts are rare today, so this is not a viable option for most hubs. However, with a collection of junk hubs, one may be able to assemble a "better-than-new" hub by measuring the parts and selecting the best-fitting ones. Using a micrometer or dial caliper, measure the length and height of each pawl and try to match like measurements into sets of three. Also, look for a combination of smallest inner diameter with largest outer diameter of the right-side pawl ring (L11). The driver surface that this pawl ring runs on should also be the largest possible. Try the operation of the right-side pawls by hand (partially assemble the internals with the right-side bearing cone finger tight — no play) and see if you can get simultaneous engagement of all three pawls. It's frustrating, but can be accomplished. Also, select bearing cones whose threads fit as tightly as possible on the axle to help eliminate gear misalignment (same cones as the AW, so availability should not be a problem). Ultimately, the "best" combination of parts will be a matter of judgment and trial-and-error fitting. If you do not have any spares to work with, converting to spring-loaded pawls may be the answer — see below.

Re-grinding pawl ring/gear ring dogs

This is best accomplished with a small sharpening stone, light oil, and a ton of patience. The idea here is to reface the dogs to be perpendicular to each other and thus eliminate the tendency to cam out against the spring. Be careful to check the fit of the gear ring with the pawl ring before reassembly, and do not remove too much material, since the parts are case hardened, not through hardened. The case depth with carburizing methods typically used by such parts is seldom very deep, and therefore this regrinding method may not last very long. (I have heard that Sturmey-Archer used the sodium-cyanide bath method of carburizing; according to my information, this method produces what is known as superficial hardness — the case depth may be only a few thousandths of an inch)[5]

I am also experimenting with a reverse-taper grind and face texturing of the dogs to help keep them in contact under load. Results will be posted here at a later date.

Polieren

Because most of the Sturmey-Archer internal parts are not machined or ground after heat treatment, their surface finish is rather rough, and they can benefit a good deal from polishing. Normally, this would be accomplished by simply using the hub, and all the parts would wear in over time to a smooth working condition. The problem with this in the SW is that the wear particles are in circulation, and may have detrimental effects on the pawls. Polishing of the pawl sockets, ball ring ramps, gear faces, driver, etc. can only help; polish with a Dremel tool or something similar as many of these areas as you can stand. For flat surfaces, a pane of flat glass with 600-grit wet/dry sandpaper and light oil can be used to produce a very smooth surface.

As the planet gears are shaper-cut gears with poor tooth precision, lapping of new gears is not a bad idea, either. This can be accomplished by assembling the gearing, introducing a bit of automotive valve-grinding paste in the mesh and spending a patient hour turning the assembly back and forth by hand. Don't use too much paste; you don't want to grind more than the surface of the gears. When finished, remove all traces of the grinding paste. Perhaps the best advice concerning polishing is to disassemble the hub and change the oil after a run-in period of, say, 50 miles or so. Wear areas that can benefit from additional polishing will then be evident. It may be good to disassemble and change the oil every year, or until little oil discoloration is encountered.

Die Sperrklinkenversenkungen neu formen

Another potential improvement to the design of the pawl rings would involve grinding a radius on the drive side edge of the pawl sockets. This would serve two purposes: reduce the tendency to dent the pawls, and improve the load sharing amongst the pawls. Also, on the left side, a soft steel retainer is pressed onto the end of the planet cage to provide end retention of the pawls. If three holes were drilled in this retainer at the bottom of the pawl sockets, the pawls would be more easily engaged in the ratchets because the oil surrounding the pawl could not create a vacuum effect.

Federvorgespannte Sperrklinken

A more-or-less permanent fix to the pawl problem can be obtained by spring-loading the pawls. I have successfully modified a right-side pawl ring to accept small bow-type springs in the bottom of the pawl sockets that keep the pawls positively engaged. This fix has virtually eliminated any skipping and has made shifting gears much more positive, and is probably the best long-term solution, producing a very reliable hub. If you are interested in modifying your hub, here's how to do it:

Using a cutoff wheel on a Dremel tool, make some shallow cuts at the bottom of the pawl sockets as shown. cutoff wheel The depth should not be too great, perhaps around 1/16th of an inch or so. Also, be careful to keep the slot as short as practical so as not to weaken the pawl ring (L11) too much. Next, some suitable spring material must be scavenged to place in these slots. I found that a camera wind-lever spring worked well for this purpose, but anything similar will do — look for flat, spiral shaped springs in old mechanical clocks, cameras, toys, etc. The final spring configuration I arrived at was about 1/16th of an inch wide and around 3/8ths of an inch long, providing firm springing action against the bottom of the pawls. If I do this again, I might try something a bit more flexible such as the film-chamber pressure plate from the same junk camera. Any thin, flat spring that can be bow-shaped will probably work. pawl ringMake sure that whatever spring material you use, your Dremel cuts are deep enough to allow the springs to be totally recessed. In operation, the large pawl retaining washer (L13) and the thrust spring (L15) will keep these pawl springs in place.

Assembly is a bit tricky because when the right-hand ball ring (L14) is placed over the pawls, the springs tend to push against the retaining washer and then pop out. I solved this problem by assembling the driver, spring, and ball ring all at the same time, and then assembling over the installed pawl ring, washer, and pawls. The thrust spring helps to keep the new pawl springs from shifting out of their grooves.

This modification has worked well with old, worn pawls and produced an assembly that virtually guarantees all three pawls will be properly engaged. The low-gear pawls would also benefit from this technique, and the pressed steel retainer on the end of the planet cage would retain the springs well. However, assembly of the completed internals into the hub shell might be very difficult to impossible — proceed at your own risk. Since the low-gear pawls are more reliable, springs are probably not needed on this side.

While sprung pawls may ultimately be the best practical fix, they do have one drawback. The hub will no longer be "silent" when coasting. In fact, the spring arrangement I have described gives a rather "bright" ticking sound similar to the AW's.

Neue Sperrklinken herstellen

The closest ANSI standard-sized Woodruff key is a no. 403, but it's only 1/8th inch wide. However, in a pinch, one might be able to combine a 403 with a 203 (1/16th wide) and with careful grinding with a Dremel tool produce the correct geometry. Woodruff keys are typically rather soft, however, and pawls made from them may not last long in service. It would be good to have access to a heat-treating facility in order to carburize the pawls after shaping them.

Die SW im Fahrbetrieb

After rebuilding and adjusting, there will probably be a period in which frequent attention is required to get the hub working consistently. Make sure the torque applied to the axle nuts is sufficient to prevent movement in the dropouts, which would adversely affect the gear adjustment and alignment.

Die Sperrklinken effektiv einklinken

One of the ironic things I have discovered about the SW is that while its pawl design is easily overloaded from slamming the pedals around, it is also easily overloaded by not engaging all three pawls, and the engagement of all three is more assured with a firm slam on the pedals. For this reason, I think that proper use of the hub involves a delicate balance between riding too hard and riding too timidly. This observation is a bit academic, however, as there is no way to judge the effectiveness of your style of riding except over long periods of time (years). Experience has taught me that the proper shifting technique is critical to eliminating troublesome slips.

Misshandlung

What constitutes abuse of these hubs? Clearly the design is not as robust as an AW hub and cannot take the abuse doled out from, say, the typical teenager. A reasonably mature adult rider should be able to obtain good service from the hub provided a few precautions are taken. Many people warn against standing up to pedal. I would also add that the chain ring/sprocket combination not differ much from the "standard" 46/18 offered on the bike. I use my 1958 Robin Hood for a relatively short urban commute and am using a 48/19 combination and I have dented the low-r pawls from aggressive acceleration (not standing). However, I also have a Hercules with a 44/19 combination that is pretty smooth and reliable after about a thousand miles of commuting (I have yet to examine its pawls). I would add, also, that unless the bicycle provides a practical means for your particular style of riding, I wouldn't bother riding it. To paraphrase Sheldon 's quote of Victor Hugo: "The useful is as useful as the beautiful", or as my ever-practical father-in-law would quip, "I didn't buy it to look at it!"

Freilaufen lassen

You are better-off limiting the amount of coasting for three reasons. First, it's not good cycling form. Second, coasting wears the pawl tips, and the less that occurs, the better. Third, if you coast frequently, you will also be engaging pawls frequently, thus increasing the chances for damage and wear.

Schalten

Unlike the relatively rapid, smooth shifting of the AW hub, the SW shifts like a garbage truck. Many times you will find yourself "chasing" an engagement for almost a full crank revolution after shifting. Upshifting usually results in a loud "ker-klunk" as the pawls and/or pawl ring engage, but sometimes there will be a simple, rapid "click" — an indicator of an improper shift. Also, I have found the downshift into low gear to be rather balky at times, to the point of irritation. While pedaling, you may occasionally hear and feel a "pop" as a pawl snaps into position. There are no improvements for this behavior, to the best of my knowledge. It's the most disappointing aspect of the SW's operation, to me.

I would also caution against what I'll call "pedal shifting" whereby upshifts are accomplished by maintaining pressure on the pedals, shifting the trigger, and then releasing the pedal pressure a bit when the actual shift is desired. I use this method to good effect in traffic with my AW hubs, but I worry that the SW may not tolerate an occasional partial engagement. Even a "fresh" SW will occasionally skip in normal or high gear if the shifting is sluggish or clumsy. Check the operation of the toggle chain and make sure there is no binding to interfere with rapid movement during gear changes. In practice, I have found that the rider develops a certain cadence for good upshifting that results in three distinct sounds, rather like a drum player's "ba-dump-bump" at the punch line of a joke. These three distinct sounds are presumably the trigger release, the pawl ring slapping against the gear ring dogs, and finally pawl engagement. If your upshift results in a simple click sound, coast a bit and re-engage because this type of shift often results in a slip. Click here for how a "good" shift sounds on one of my bikes (I recorded this whilst riding).

Schmierung

As mentioned above, my recommendation for a lubricant is fairly thin oil such as automatic transmission fluid (ATF). I think this is especially important for the SW because with heavy oil, pawls may tend to stick in their sockets and resist being tripped into position — ultimately leading to wear and/or chipping. I have also used motorcycle transmission oil (Gearsaver by Belray), which is a thin oil replacement for 80W gear oil (equivalent viscosity to 20W motor oil, but it's actually very thin at room temperature). It's a bit thicker than regular ATF, but otherwise seems very similar; it seems to stick to the parts a little better so a good film remains after several hours of idle time. 75W gear oil (same viscosity as 10W motor oil) may prove to be an excellent lubricant, as well, although there really isn't any need for much EP additive since there are no hypoid gears. I also recommend parking the bike in an upright position to eliminate the possibility of oil starvation of the right-side pawls.

All this special attention to oil will be rather unnecessary if using sprung pawls. In that case, I would imagine the selection of oil does not matter very much.

The recommended amount of oil in the hub at any given time is great mystery to me. These hubs tend to leak whatever oil they have, especially if you have the old-style metal lubricator cap. Sturmey-Archer have suggested two teaspoons poured into the internals upon initial assembly and replenishments of a few drops at a time. It is unclear to me what level of oil, if any, this practice was intended to maintain. Too much oiling doesn't do any harm to the hub, but it will ruin the effectiveness of the rear brake if one does not keep after the mess. I have adopted a "little and not very often" approach which seems to keep the hubs working well and relatively clean.

Laufradbau

I have found 283 mm spokes to work well with a 40-hole Endrick-style steel Dunlop rim, laced "cross 4". For a Raleigh-patent rim, shorter spokes are needed, and I think 277 mm would work (based on an old Raleigh spoke chart, the difference between Raleigh and Endrick rims is 1/4 inch, or about 6 mm for the AW).

Fußnoten

- ↑ John Allen merkt hierzu an: Die AW Nabe gabe es allerdings einige Jahre mit einem Aluminium-Körper. Die SW hingegen nicht.

- ↑ John Allen merkt hierzu an: Das stimmt so nicht ganz, weil Drehmoment und keine längsgerichteten Kräfte übertragen werden und weil der Planetenkäfig sich selbst ausrichten kann. Allerdings sind die Zähne der Zahnräder angewinkelt und nicht radial. Eine radiale Abweichung von sich gegenüberliegenden Planetenrädern wird zur tangentialen Abweichung des anderen Paares.

- ↑ Das stammt aus dem schönen Buch "The Sturmey-Archer Story" von Tony Hadland, 1987 (Partnerlink). Sheldon Brown meint: "Versuch' es zu bekommen, es ist wirklich sehr schön!"

- ↑ Ergänzung zu Tony Hadlands Website

- ↑ Aus dem Machinery's Handbook 24th ed., Robert Green, Industrial Press, 1992 (Partnerlink)

Siehe auch

- Sheldon Browns Übersetzungsrechner (in mehreren Sprachen verfügbar)

- Offizielle Sturmey-Archer Website

- Techniktipps zu Sturmey-Archer Nabenschaltungen

- Alles über Nabenschaltungen

- Sturmey-Archer Naben

- Demontage von Sturmey-Archer Naben

- Wartungsanleitung für die Sturmey-Archer AG Nabe und den Dynohub

- Verwendung und Wartung von Sturmey-Archer Schaltungsnaben

- Sturmey-Archer Teile und Namen

- Modell- und Produktionsjahrbestimmung von Sturmey-Archer Nabenschaltungen

- Spezifikationen (PDF/englisch)

- Ersatzteile (für die meisten Naben, außer bei individuellen Einträgen entsprechend erwähnt) (PDF/englisch)

- RaleighChopper.info mit Informationen zu vielen Naben (englisch)

- Vancruisers.ca mit Informationen zu vielen Naben (englisch)

- Sutherland's Handbook of Coaster Brakes and Internally-Geared Hubs (englisch)

- Sturmey-Archer 1951 Service Manual on the Sturmey-Archer Heritage site (englisch)

- Sturmey-Archer 1951 Service Manual on Vancouver Van Touring site (englisch)

- 1956er Wartungsanleitung und Informationen von 1902 bis 2001 auf Tony Hadlands Website (englisch)

- 1956er Wartungsanleitung auf www.toehead.plus.com (englisch)

- Offizielle Unternehmenswebsite von Sturmey-Archer (englisch)

- Sturmey-Archer Heritage Website (englisch)

- Drei-Gang-Naben Ersatzteile, Hätscheln und Tätscheln

- Alles über Nabenschaltungen

- Allgemeine Informationen zu Sturmey-Archer Naben

- Sturmey-Archer 50 Jahre Marktführer

- Sturmey-Archer Naben Verkaufsbroschüren von 1935 und 1938

- Sheldons altes Robin Hood (englisch)

- Martin Hanczycs Roadster Seiten (englisch)

- 1956er Hauptkatalog (PDF/englisch)

- Hubstripping Website (englisch)

- John Allens Tabellen zu Übersetzungen bei Nabenschaltungen (englisch)

- Retro Raleighs

Quelle

Dieser Artikel basiert auf dem Artikel Sturmey-Archer SW Three Speed Bicycle Hubs von der Website Sheldon Browns. Originalautor des Artikels ist Brian Hayes.

- S3X

- Die Sturmey-Archer ASC Fixed Gear Drei-Gang-Nabe

- Sturmey-Archer Naben

- Fehlersuche bei der Sturmey-Archer Sprinter Fünf-Gang-Nabe

- Die Sturmey-Archer Sprinter Fünf-Gang-Nabe

- Die Sturmey-Archer ASC Fixed Gear Drei-Gang-Nabe/Wartung der Sturmey-Archer ASC Fixed Gear Drei-Gang-Nabe

- Quadrant Shifter

- Dynohub

- SunRace